Introduction: Computer Numerical Control (CNC) lathes have revolutionized the manufacturing industry by offering precision, efficiency, and versatility. These machines are equipped with various components that work together seamlessly to produce intricate parts and components. In this guide, we will provide a detailed overview of the essential CNC lathe parts, their functions, and their role in the CNC machining process.

- Bed and Base: The bed and base are the foundation of the CNC lathe machine. They provide stability and support to all other components. The bed is typically made of heavy-duty cast iron to minimize vibrations and ensure rigidity. It serves as a mounting platform for various components, including the headstock, tailstock, and carriage.

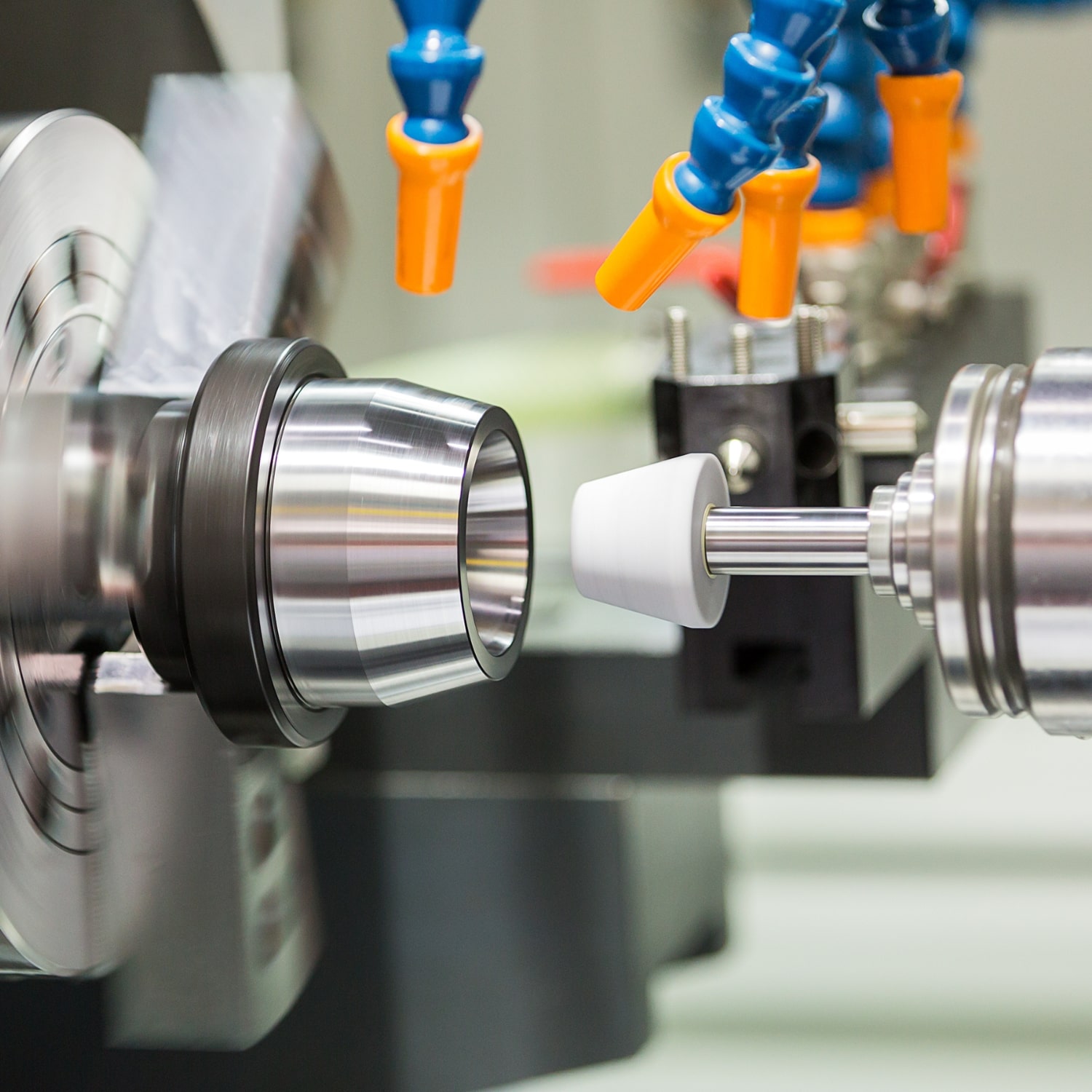

- Headstock: The headstock houses the spindle, which is responsible for rotating the workpiece. It contains several vital components: a. Spindle Motor: This motor provides the power needed to rotate the spindle at various speeds. b. Spindle Bearings: These precision bearings ensure smooth and accurate rotation. c. Chuck: The chuck securely holds the workpiece in place while it is being machined. d. Gearbox: The gearbox allows for speed and feed rate adjustments, ensuring the right cutting conditions.

- Tailstock: The tailstock is located at the opposite end of the lathe from the headstock. Its primary function is to provide support to the workpiece, especially when machining long parts. Key tailstock components include: a. Tailstock Quill: The quill can be extended or retracted to apply pressure against the workpiece, securing it in place. b. Tailstock Center: The tailstock center supports the workpiece at its center, ensuring accurate machining.

- Carriage: The carriage is a movable assembly that holds the cutting tool and moves along the bed’s horizontal axis (X-axis). It includes several significant components: a. Saddle: The saddle is the part of the carriage that moves along the bed. b. Cross Slide: The cross slide moves perpendicular to the bed (Z-axis) and carries the tool holder. c. Tool Post: The tool post holds the cutting tool, allowing it to be positioned accurately.

- Tooling and Tool Holders: CNC lathes use a variety of cutting tools to shape workpieces. Tooling components include: a. Cutting Inserts: These replaceable tips are made from carbide or other materials and come in various shapes and sizes for different machining operations. b. Tool Holders: Tool holders secure cutting inserts in place and provide the necessary rigidity during machining. c. Tool Turrets: Some CNC lathes are equipped with automatic tool turrets that can hold multiple tools, allowing for rapid tool changes.

- Control Panel and CNC Software: The control panel is the interface between the operator and the CNC lathe. Operators input commands and program the machine through the control panel. CNC software interprets these commands and controls the movements of the various machine components. It also manages tool changes, spindle speed, and feed rates to produce accurate parts.

- Servo Motors and Drives: Servo motors are responsible for precise movement control in CNC lathes. They receive signals from the CNC software and drive the axes (X, Z, and sometimes additional axes) to position the cutting tool accurately. Drives are responsible for converting electrical signals into mechanical motion.

- Coolant System: Coolant systems are essential for maintaining temperature control and chip removal during machining. They help prevent overheating of cutting tools and workpieces and improve surface finish.

- Chip Conveyor: During the machining process, metal chips are generated and need to be efficiently removed from the work area. Chip conveyors transport these chips away from the machine to keep the workspace clean and safe.

- Lubrication System: A CNC lathe’s moving parts require proper lubrication to reduce friction and wear. Lubrication systems ensure the machine operates smoothly and extends its lifespan.

Conclusion: Understanding the various components of a CNC lathe is crucial for operators and those involved in CNC machining. These components work in harmony to transform raw materials into precision-engineered parts, making CNC lathes indispensable in industries ranging from automotive manufacturing to aerospace. As technology continues to advance, CNC lathe components are continually improving, allowing for even greater precision and efficiency in machining operations.