The injection molding process allows plastic manufacturer to produce identical plastic parts on a mass scale. This revolutionary technology has enabled the creation of countless products that benefit our everyday lives. However, with any breakthrough innovation comes the need to protect intellectual property rights. This article explores the legal aspects of injection molding, focusing on how patents, copyrights, and trademarks apply to this industry.

An Overview of Injection Molding

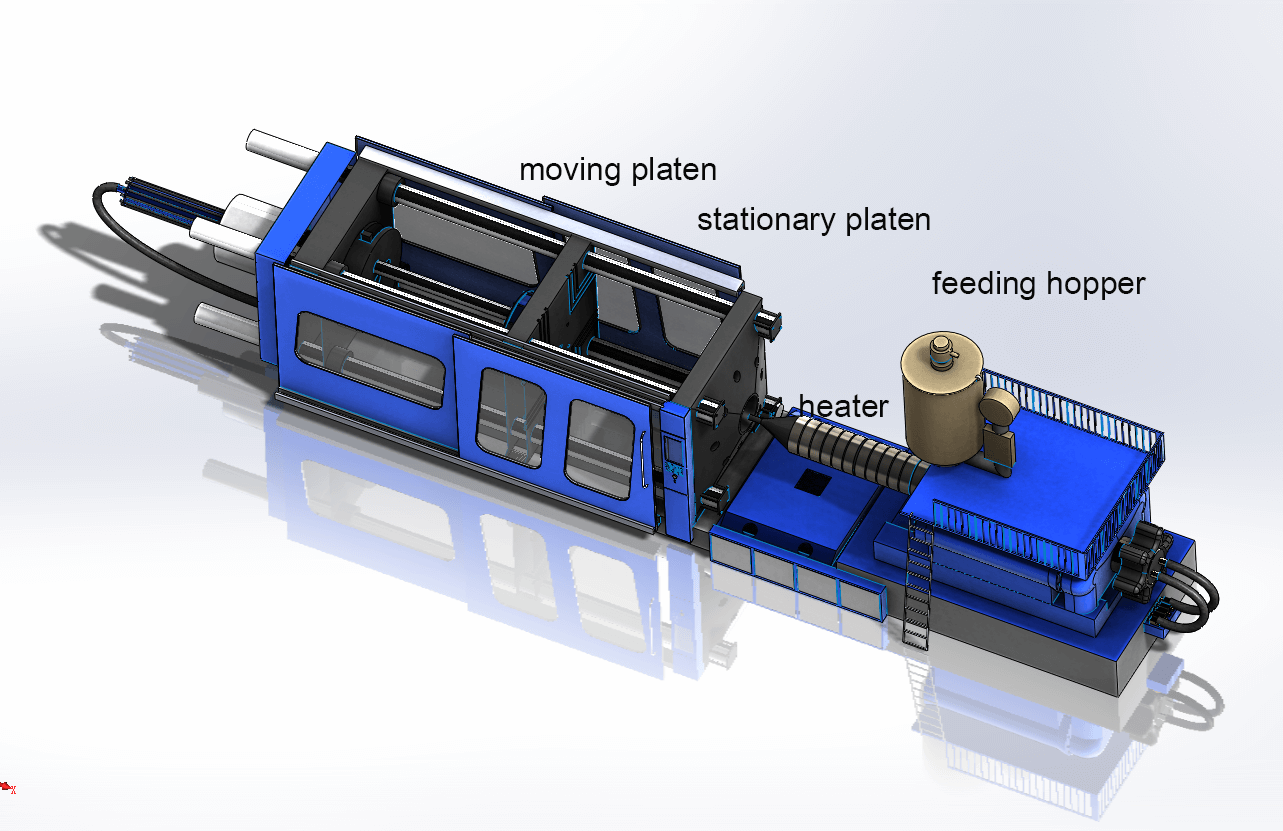

Injection molding is a manufacturing technique in which heated plastic is injected under high pressure into a mold cavity. The mold is made from tool steel and shaped to form the external shape of the desired part. Once the plastic has sufficiently cooled and hardened, the mold opens and the part is ejected. The cycle then repeats to create identical replicas of the part in high volumes.

Some key advantages of injection molding include:

- Cost-effectiveness – Producing parts via injection molding is economical compared to other manufacturing methods due to its rapid production rates and ability to minimize material waste.

- Consistency – The closed mold system ensures consistent production quality and minimal variations between parts.

- Complexity – Intricate part geometries with fine details can be fabricated, beyond the capabilities of other techniques.

- Material flexibility – A wide range of plastic polymers can be injection molded, including polyethylene, polypropylene, polystyrene, acrylic, ABS, nylon, and more.

- Assembly consolidation – Multiple components can be integrated into a single injection molded part, eliminating assembly steps.

Given these benefits, it’s no surprise injection molding has proliferated across industries like automotive, consumer goods, medical devices, and more. However, the broad applicability of this technology also necessitates protections for unique inventions and brand identities.

Why Intellectual Property Matters in Injection Molding

Intellectual property (IP) allows individuals and companies to legally claim ownership of their creative work or brand. With regards to injection molding, key forms of IP include patents, copyrights, and trademarks. Properly leveraging these tools provides critical advantages:

Patents Protect Innovative Technologies

A patent provides its owner with a limited monopoly over a novel functionality or design. This prevents competitors from utilizing patented technologies for commercial gain without authorization or compensation. For injection molding operations, patents safeguard proprietary mold designs, product features, manufacturing processes, tooling mechanisms, automation systems, and more. Robust patent portfolios ensure that R&D investments yield exclusive rights to the resulting advancements.

Copyrights Preserve Original Works

While patents cover functional creations, copyrights pertain to artistic works like writings, images, schematics, and 3D model files. In injection molding, technical drawings, CAD files, and other design documents can be copyrighted to control their distribution and prevent unauthorized copying. This guards against counterfeit products based on stolen digital designs.

Trademarks Build Brand Recognition

Trademarks provide exclusive use of logos, names, or symbols that identify a company’s products and services. Well-known plastic brands leveraging injection molding rely on trademarks to build customer recognition. Trademarks also help prevent other businesses from creating knock-off products that unfairly profit from an established brand’s reputation.

With innovation fueling growth in the injection molding sector, proper IP measures are crucial. Next, we’ll explore how patents, in particular, apply to this industry.

Patents: Safeguarding Injection Molding Inventions

Patents provide powerful protections for the novel technologies and designs underpinning modern injection molding operations. However, patents also impose stringent requirements. Meeting the main patentability criteria demands strategic IP practices:

Demonstrating Novelty

To be patentable, an invention cannot already exist within public knowledge. It must represent a new, original concept rather than an obvious improvement over known solutions. Thorough prior art searches are thus critical when seeking patents. Analyzing existing patents, academic publications, product catalogs, and more can reveal if a proposed injection molding-related invention has already been publicly disclosed. This due diligence strengthens novelty claims when applying for patents.

Proving Non-Obviousness

Another requirement is that an invention cannot simply combine familiar technologies in an obvious manner. The innovation should represent an unexpected, non-trivial advancement over conventional injection molding approaches. Evidence like competitive advantages, expert testimonials, or commercial success can substantiate non-obviousness.

Detailing Operability

Patent applications must fully explain an invention to prove it actually works as intended. Accordingly, injection molding innovations should be thoroughly documented by flow diagrams, control logic, mechanical schematics, material specifications, processing parameters, and more. Ambiguous or theoretical concepts lack sufficient operability support when filing for patent protection.

Meeting Filing Deadlines

Missed patent filing deadlines can irrevocably forfeit rights to an invention. Once publicly disclosed, inventions lose novelty status and opportunities for patent exclusivity. After one year of public use in the U.S., or any public disclosure globally, valid patent filings become impossible. Early submission, often in the form of provisional applications, helps avoid such bars.

With sound IP practices, injection molding enterprises can consistently secure patents on their leading-edge solutions, sustaining an edge over competitors.

Copyright Considerations for Injection Molding Design

While patents protect novel functionalities, copyrights preserve original creative works related to injection molding operations. Various design assets qualify for copyright registration:

Product Design Drawings

CAD renderings, technical sketches, and engineering drawings depicting injection molded parts or molds can be copyrighted. This grants the creator exclusive rights to reproduce, distribute, modify, perform, or display these images. Most visual works have copyrights automatically at creation, but registration enhances enforceability.

Digital Model Files

The 3D model files used for simulating mold injection cycles or programming CNC machining of mold tooling also constitute creative works eligible for copyright. STL, IGES, STEP, and other CAD file formats can be protected from unauthorized duplication and distribution via registration.

Instruction Manuals

Written manuals for operating injection molding equipment, performing mold maintenance, troubleshooting issues, or processing specialized materials qualify for copyright as literary works. The same applies to mold design handbooks disseminated among engineering teams.

Branding Graphics

Artistic assets like company logos, marketing brochures, trade show signage, and web images featuring injection molded parts fall under copyright domains. Registering copyrights on branding assets used across promotional mediums prevents other companies from co-opting these materials.

Like patents, copyrights empower businesses to fully capitalize on their intellectual output while excluding free riders. Registering copyrights early in the development cycle ensures proper protections are in place as assets are rolled out to the public.

Leveraging Trademarks in Injection Molding

Trademarks provide exclusive use of the logos, names, symbols, slogans, and designs associated with branded products or services. Major global manufacturers using patented injection molding technologies rely heavily on trademarks to build customer recognition. But trademarks are equally crucial for small and mid-sized molding operations looking to grow their brand.

Selecting Strong Trademarks

Ideally, trademarks clearly reflect an injection molding company’s identity and offerings in a unique memorable way. Strategically coined names, stylized logos, and punchy slogans aid brand recall. Distinctive naming can even communicate competitive strengths, as with MoldWorks Innovations® emphasizing creative mold designs.

Registering Trademarks

While trademarks arise automatically through use in commerce, registration creates far stronger protections. The registered ® symbol next to a trademark signals exclusive national ownership of the mark. Registration also enables legal recourse against infringing uses that cause customer confusion or dilute brand equity.

Using Trademarks Properly

Proper formatting is key when applying trademarks commercially. They should always appear distinctly as adjectives preceding the generic product or service term. For example, a molded parts business should reference its Soul Injection® injection molding services, not a Soul Injection service. Consistent trademark usage reinforces recognition.

Expanding Brand Scope

As offerings expand, extending trademarks to cover new services prevents branding fragmentation. A mold manufacturer could designate its original ToolWorks® trademark for machined molds while reserving InjectWorks® for its newer molding service. Keeping trademarks and registrations current maximizes coverage.

Vigilant trademark management represents yet another intellectual property aspect that secures competitive advantages for injection molding ventures.

IP Takeaways for Injection Molders

This overview highlights why intellectual property considerations are integral, not ancillary, to success in the injection molding sector. Key lessons for protecting innovations include:

- Aggressively pursue patents on novel product designs, manufacturing methods, automation systems, and other proprietary advancements. Prior art searches, detailed documentation, and rapid filing help satisfy stringent patent requirements.

- Register copyrights early to control copying of CAD files, drawings, manuals, and artistic branding assets used in injection molding operations.

- Select unique trademarks that reflect brand identity, and formally register them to strengthen enforceability against infringement.

- Continually expand trademark scope and registrations as new services and offerings are introduced.

- Monitor competitor activities for potential patent or trademark infringements that unfairly exploit protected intellectual property.

- Work with qualified IP attorneys to develop comprehensive IP strategies encompassing all available protections.

With plastic manufacturing only becoming more sophisticated, the companies able to stake claims to emerging technologies and brand identities will have the upper hand. By fully leveraging patents, copyrights, trademarks, and other IP tools, injection molding enterprises can assert their innovations while excluding unauthorized use. A vigilant intellectual property approach helps secure the full commercial benefits of novel designs and production capabilities.