Introduction

In the realm of construction and renovation, precision is paramount. Whether you are a professional contractor or a DIY enthusiast, having the right tools at your disposal can make all the difference. One such tool that plays a pivotal role in achieving precision cuts in various construction projects is the wall saw blade. In this comprehensive guide, we will delve into the world of wall saw blades, exploring their features, applications, and why they are indispensable for anyone working with concrete, masonry, or other similar materials.

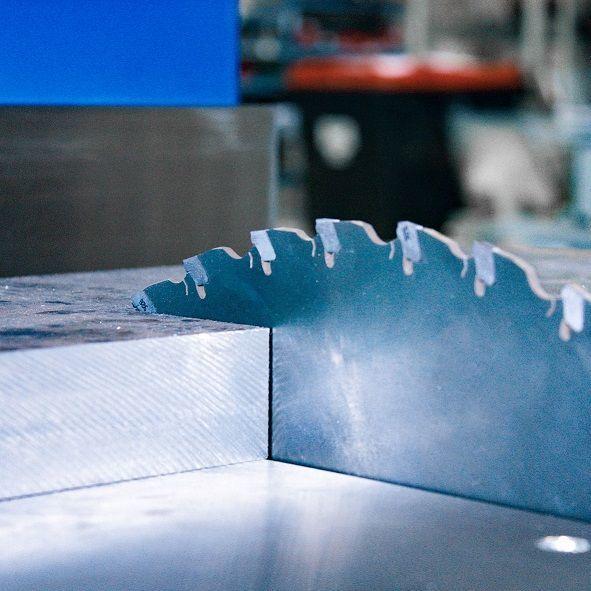

Wall Saw Blade: The Heart of Precision Cutting

When it comes to cutting through tough materials like concrete or masonry walls, a wall saw blade is the unsung hero. This cutting-edge tool is designed to perform in the most demanding conditions, providing clean and precise cuts. Here’s everything you need to know about wall saw blades:

Anatomy of a Wall Saw Blade

Before we dive deeper into the applications and benefits, let’s dissect a wall saw blade and understand its key components:

- Diamond Segments: The cutting edge of a wall saw blade is adorned with diamond segments. These industrial-grade diamonds are precisely bonded to the blade’s core, ensuring exceptional durability and cutting efficiency.

- Core Material: The core of a wall saw blade can be made from various materials, including steel or alloy. It provides stability and maintains the blade’s shape during operation.

- Gullets: These are the spaces or slots between the diamond segments. Gullets play a crucial role in dissipating heat generated during cutting, preventing overheating.

- Segment Arrangement: The arrangement of diamond segments can vary, with different patterns designed for specific cutting tasks. A segmented rim is ideal for general-purpose cutting, while turbo or continuous rims offer faster cutting speeds.

Applications of Wall Saw Blades

Wall saw blades are versatile tools suitable for an array of applications:

- Concrete Cutting: Wall saw blades excel at cutting through concrete walls and slabs, making them indispensable in construction projects.

- Masonry Work: Whether you need to create openings for doors or windows or make precise cuts in brick or stone, wall saw blades are your go-to choice.

- Renovations: When renovating a space, wall saw blades allow for controlled and precise demolition, minimizing damage to surrounding structures.

- Utility Installations: Installing pipes, conduits, or HVAC systems often requires precise cuts in concrete walls, which can be effortlessly achieved with wall saw blades.

- Rescue Operations: In emergency situations, such as search and rescue missions, wall saw blades can quickly cut through debris to access trapped individuals.

Advantages of Wall Saw Blades

Why choose wall saw blades over traditional cutting methods? Here are some compelling advantages:

- Precision: Wall saw blades offer unmatched precision, resulting in cleaner cuts and reduced material wastage.

- Speed: With their cutting-edge design, wall saw blades work quickly, saving time on your projects.

- Versatility: They are suitable for various materials, making them a versatile tool in your arsenal.

- Durability: Diamond segments and robust core materials ensure longevity, making wall saw blades a cost-effective choice in the long run.

FAQs about Wall Saw Blades

- What is the difference between a wall saw blade and a regular saw blade? Wall saw blades are specifically designed for cutting through tough materials like concrete and masonry. They feature diamond segments for enhanced cutting efficiency and durability, which regular saw blades lack.

- Do I need special training to use a wall saw blade? While basic knowledge of operating power tools is helpful, specialized training is recommended for safe and efficient use of wall saw blades. Always follow manufacturer guidelines.

- Can wall saw blades be used for dry cutting? Wall saw blades can be used for wet or dry cutting, depending on the blade’s design and your specific cutting requirements. Wet cutting is preferred for dust control and cooling.

- How long does a wall saw blade last? The lifespan of a wall saw blade depends on factors like usage frequency, material type, and maintenance. On average, a well-maintained blade can last for several projects.

- Can wall saw blades be sharpened or repaired? Wall saw blades with worn-out or damaged diamond segments are typically replaced rather than sharpened or repaired. Attempting to repair them can compromise safety and cutting performance.

- What safety precautions should I take when using a wall saw blade? Always wear appropriate safety gear, including eye protection, ear protection, and a dust mask. Follow all safety instructions provided by the manufacturer.

Conclusion

In the world of construction and renovation, precision is non-negotiable, and the t sagment blade stands as a testament to achieving it. With its cutting-edge design, durability, and versatility, it has become an indispensable tool for professionals and DIY enthusiasts alike. Whether you are embarking on a concrete cutting project or need to make precise openings in walls, the wall saw blade is your trusted companion for achieving superior results.

So, next time you find yourself in need of precise cuts in challenging materials, remember the wall saw blade – the key to unlocking the world of precision.